Product Details

Product Introduction

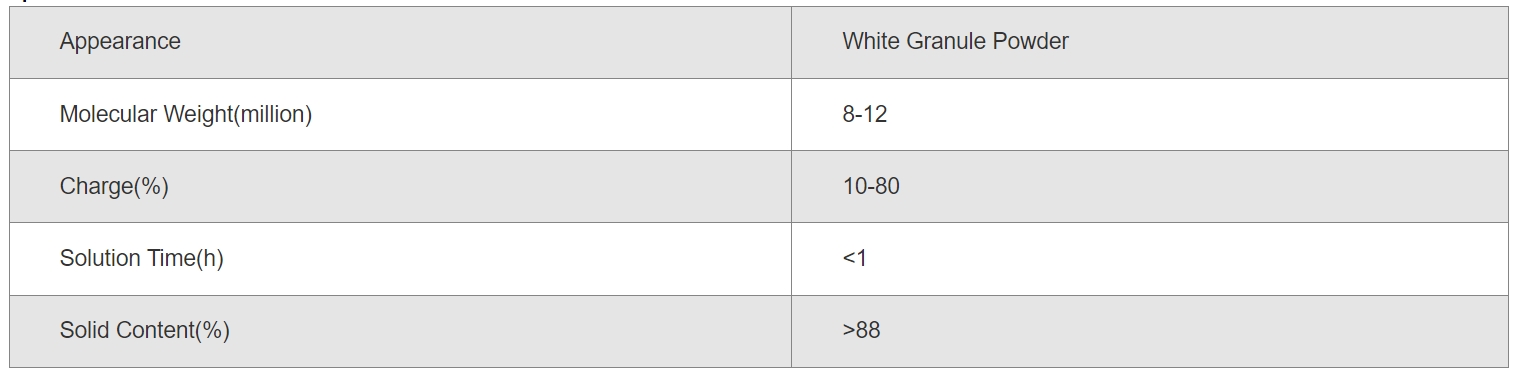

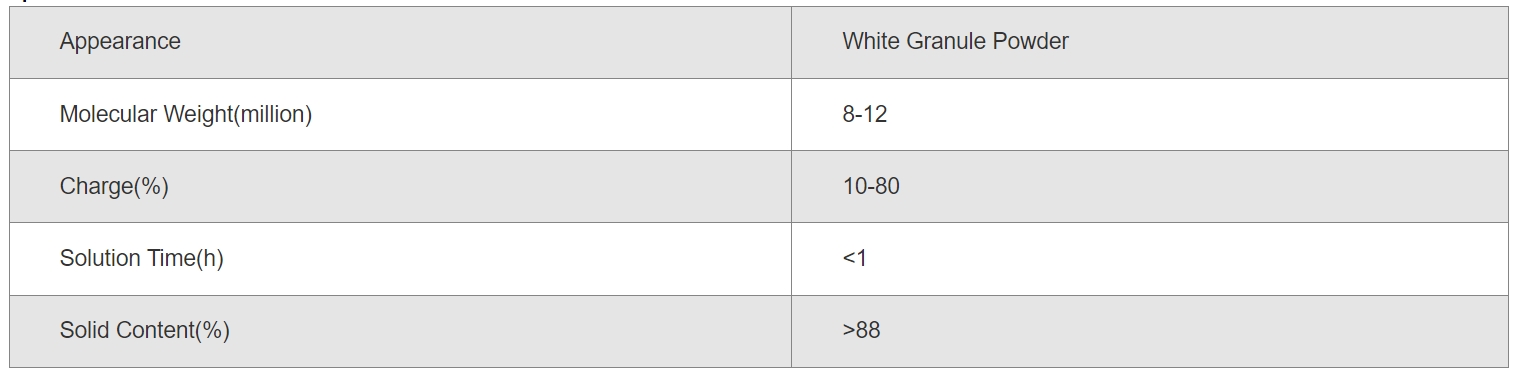

Polyacrylamide (PAM) is a vital reinforcing agent utilized in both wet and dry processes across various industries. It is categorized into four types: anionic, cationic, nonionic, and zwitterionic. The molecular formula of PAM is C3H5NO, accompanied by a CAS number of 9003-05-8. Our enhancements for both applications have been rigorously certified under ISO, S9001, SO14001, and OHSAS, which guarantees high standards of quality and safety. This product appears as a white granular powder with a high molecular weight ranging from 8 million to 12 million and a solid content exceeding 88%. A notable benefit of PAM is its role as an efficient fixative during the wet end processes of paper production, where minimal dosages can yield significant results. It is compatible with both acidic and neutral sizing systems in papermaking. Cationic PAM enhances the fixation rate of fillers and fine materials throughout the papermaking process via bridge flocculation, subsequently accelerating the drainage of paper materials within the machine's mesh and enhancing cationization within the particle system, which results in larger flocs. This mechanism significantly improves the forming effect and overall quality of the produced paper.

Advantages and features

1. Our products are certified to various standards, including ISO, S9001, SO14001, and OHSAS, ensuring adherence to stringent quality and safety regulations. 2. They exhibit a molecular weight ranging from 8 million to 12 million, coupled with a solid content exceeding 88%, delivering outstanding reinforcement properties. 3. The bridging flocculation mechanism significantly enhances the retention of fillers and fine materials during the paper manufacturing process. 4. With a dissolution time of under 1 hour, our products facilitate rapid and efficient operations and are broadly applicable. 5. The use of cationic PAM aids in improving drainage efficiency and sheet formation in paper production, thereby enhancing the overall quality of the final product.

Application Scenario

1. Perfectly suited for a range of applications in industrial wastewater treatment and municipal sewage management. 2. Extensively utilized across diverse sectors, such as oil extraction, metallurgy, coal processing, and sand washing. 3. Appropriate for both acidic and neutral sizing processes in the papermaking industry.

.png)