Product Details

Product Introduction

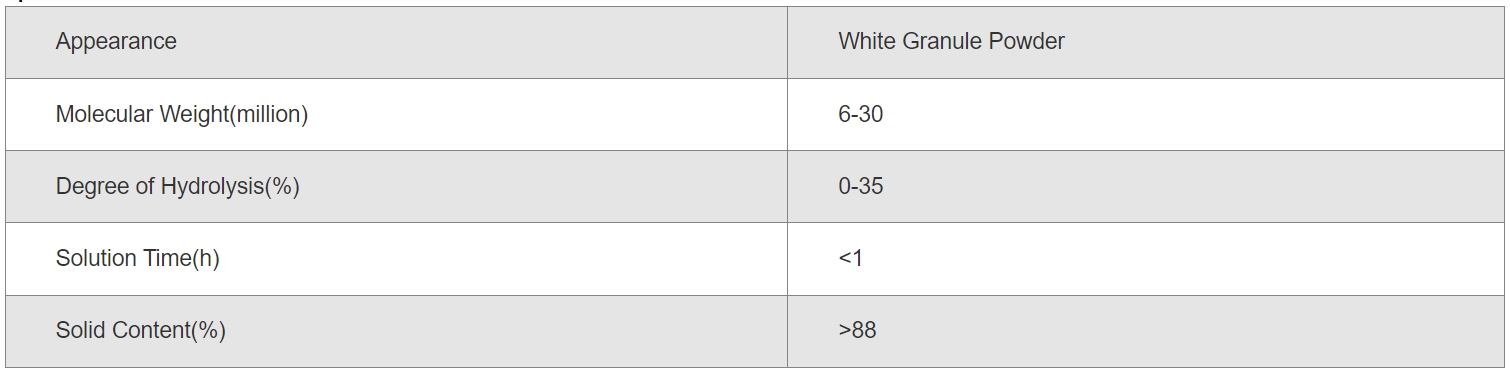

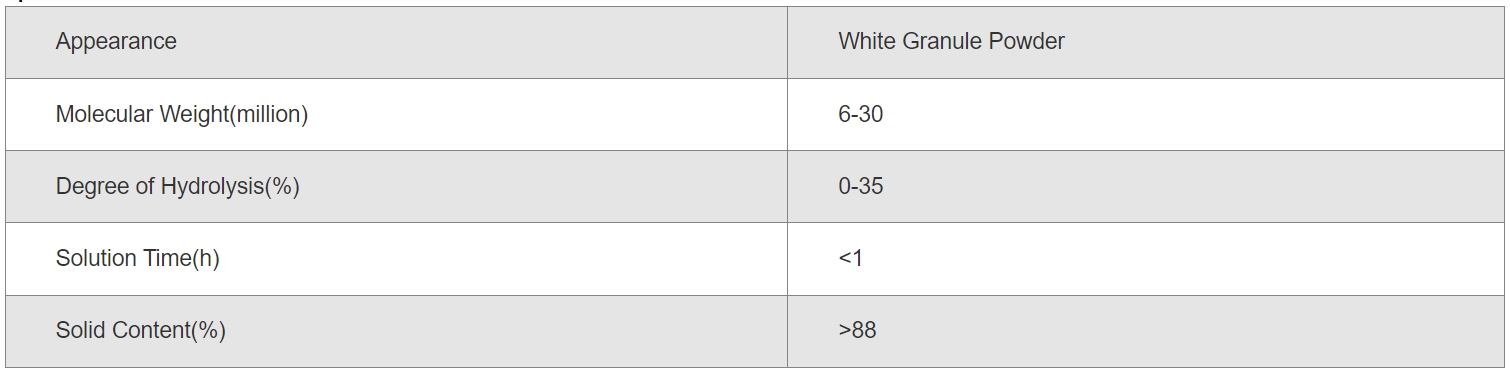

Polyacrylamide (PAM) is an effective chemical additive available in different types, including anionic, cationic, nonionic, and zwitterionic categories. It has a molecular formula of C3H5NO, a CAS number of 9003-05-8, and has received various international certifications, such as ISO, S9001, ISO14001, and OHSAS, which guarantee its quality and safety. PAM is typically packaged in 25KG paper-plastic composite bags, with customization options available per order requirements. This product finds extensive application across numerous industrial sectors, particularly in the transportation of crude oil and refined oil through pipelines. It significantly minimizes flow resistance, consequently enhancing pipeline throughput while decreasing energy consumption. Additionally, PAM exhibits notable corrosion inhibition properties for pipelines. It appears as a white granular powder, with a molecular weight range of 6-30 million, a hydrolysis degree of 0-35%, a solution time of less than 1 hour, and a solid content exceeding 88%.

Advantages and features

1. Exceptional efficiency: Our high-energy PAM thickener delivers outstanding flocculation, thickening, and drag reduction properties, making it suitable for diverse industrial applications. 2. Premium raw materials: We utilize high-purity raw materials with a molecular weight range of 6-30 million, ensuring the stability and efficacy of the product. 3. Extensive certifications: Our product boasts multiple international certifications, including ISO, S9001, ISO14001, and OHSAS, guaranteeing top quality. 4. Customizable packaging: Supplied in standard 25KG paper-plastic composite bags, packaging can be tailored to meet specific order requirements for easy transportation and storage. 5. Strong corrosion resistance: This product significantly inhibits corrosion during pipeline transportation, aiding in the prolongation of equipment lifespan and reduction of maintenance costs.

Application Scenario

1. Transportation of crude oil and refined oil products through pipelines to enhance throughput and minimize energy usage. 2. Treatment of industrial wastewater and urban sewage to boost efficiency in the processing. 3. Solid-liquid separation and thickening processes in sectors like mining and sand washing.